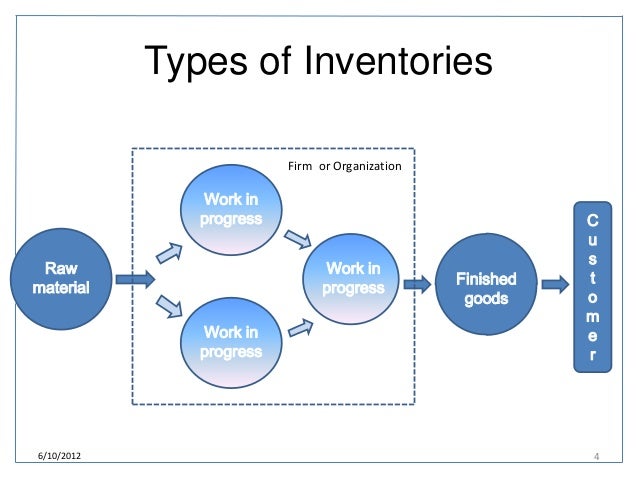

TYPE OF INVENTORY

RAW MATERIAL

Raw material Any item used to manufacture components or finished products. These can be items produced directly by your business or purchased from a supplier. For example, the potato chips making business may purchase raw materials such as potato, turmeric and salt

WORK-IN PROGRESS INVENTORY

Works-in-progress inventory refers to unfinished items to move through production but not yet ready for sale. In the case of the candle-making business, the work-in-progress inventory may be potato chips that are drying and unpacked.

MAINTENANCE, REPAIR AND OPERATION (MRO)

Maintenance, Repair and Operation (MRO) Goods Items used to aid and facilitate the production of finished goods. These items are commonly used as a result of the production process, but are not a direct part of the finished product. For example, disposable molds used to manufacture potato chips would be considered MRO inventories.

FINISH GOODS (FG)

Finished goods are products that have completed the production process and are ready to sell: the potato chips themselves.

Comments